“According to industry estimates, at least one-third of food recalls in North America may be directly related to sanitation, hygiene and material handling issues within food facilities. On a related note, The CDC lists unsanitary equipment and surfaces as one of the top five contributing factors of foodborne illness outbreaks. The Model HWF provides the enhanced food safety segment with a long-awaited continuous weighing solution that drives process efficiencies,”

said Allen McIntosh, Thayer Scale, Sanitary – Food | Pet Care Business Segment Manager.

Thayer Scale’s Model HWF Hygienic Weigh Feeder is designed and built in accordance with the applicable provisions of 3-A, USDA, and NSF design standards to:

- Provide accurate and repeatable in-process bulk material flow rate measurement for mass balance calculations and process control.

- Reduce sanitation time – the HWF disassembles quickly without hand tools to optimize sanitation effectiveness.

- Tolerate high pressure, high-temperature sanitation evolutions without calibration drift or compromising measurement sensitivity.

- Provide a long-term, low cost of ownership with rugged, “Built-to-Survive” construction.

- Assist with CGMP, HACCP and HARCP program compliance.

The Food Safety Modernization Act (FSMA) transformed the nation’s food safety system by shifting the focus from responding to foodborne illness to preventing it. Since this law’s passage, additional food traceability rules and food safety plan requirements have emerged for the sanitary space. Thayer Scale developed the Hygienic Weigh Feeder to help the sanitary space meet the challenges of this new era of smarter food safety initiatives.

A major customer-brand leader of dairy products, whose annual sales exceed $5 billion, has placed an initial, multi-unit HWF order to improve cheese conversion (shred) lines at multiple sites. The HWF units accurately measure the flow rate of cheese discharged from in-line centrifugal shredders so that anti-clumping agents (dispensed by Thayer Scale vibratory tray-based Loss-In-Weight feeders) can be applied in precise proportion to the measured cheese flow rate, as well as in phase with the fluctuating cheese profile.

“We are excited to add the model HWF Hygienic Weigh Feeder to our industry-leading product line of precision weighing solutions. This continues the aggressive push Thayer Scale has made into the food processing market segments, including coffee, snack foods, gummies, pet food, and other major sub-segments. Our strong commitment to innovation, quality and product development is unparalleled in the bulk solid weighing industry,”

said David Hyer, President, Thayer Scale.

The post Thayer Scale Announces Launch of New Hygienic Weigh Feeder for High Accuracy Weighing appeared first on BulkInside.

在治疗非胰岛素依赖型2型糖尿病和肥胖中,二甲双胍(化学1,1-二甲基双胍)用于降低血糖水平,…< / p > < p >的<一个rel =“nofollow”href = " //www.fxmrh.com/bulk-solids-handling/size-volume-reduction/metformin-preparation-station-with-potential-to-become-a-bestseller/ " >二甲双胍准备站与潜在成为畅销书< / >第一次出现在< rel =“nofollow”href = " //www.fxmrh.com " > BulkInside < / >。< / p >

Metformin preparation station for efficient production

With the new metformin processing station, L.B. Bohle enables efficient and large-volume processing of metformin. The mobile station crushes, de-clusters, and screens the metformin, which is then transferred by vacuum to the fluid bed system BFS positioned next to it.

The raw material in form of solid blocks is manually unpacked by the operator and placed on a lifting device at an ergonomic height. By means of convenient control on the HMI, the platform with the product is lifted and the metformin block is fed to the chopper unit. Complete dust extraction is always ensured via an extraction system.

Flexible use thanks to various screen inserts

A BTS Turbo Sieve is connected directly below the chopper unit to sieve the chopped metformin blocks. Various screen inserts with different diameters can be used. A suction shoe is connected to the outlet of the BTS, which provides a connection to the vacuum transfer system of the Bohle fluid bed system.

Advantages at a glance:

- Compact design – mobile and flexible integration in the production setup

- Comfortable operation via HMI. Only one operator is needed for loading.

- Fast unpacking of metformin blocks at an ergonomic height

- Short production cycle – approx. 40 seconds.

- Fast disassembly for cleaning. A lifting column is required for complete dismantling of the feeding hopper and chopper

- Highest flexibility due to the use of different screen inserts

- Integrated vibrator

- Inspection of the process – unobstructed view into the feed hopper and chopper

- Direct suction at the feed hopper possible

The post Metformin Preparation Station with Potential to Become a Bestseller appeared first on BulkInside.

The post Flexicon Introduce Access Platform Line appear first on BulkInside.

. .. .. .. .. .The modular system includes braced frames which can be bolted to the floor, 1220 mm square deck sections, and stairways with elevations up to 2.4 m.

Upper grab rails and mid-height rails bolted to stairway stringers and deck perimeters, together with auto-closing hinged safety gates and anti-slip grating on treads and decks, maximise personnel security.

Modularity allows stacking of frames to attain high elevations, and joining of decks in 1220 mm square increments to create elevated walkways and extended mezzanine areas in shapes conforming to equipment configurations and plant layouts.

Control panels can be mounted to the braced frame, allowing operation of equipment at various elevations.

The company also manufacture flexible screw conveyors, pneumatic conveying systems, tubular cable conveyors, bulk bag dischargers, bulk bag conditioners, bulk bag fillers, manual dumping stations, drum/box/container tippers, weigh batching systems, and automated plant-wide systems integrated with new or existing process equipment.

For information contact Flexicon Europe Ltd, +44 (0)1227 374710, sales@flexicon.co.uk, www.flexicon.co.uk

The post Flexicon Introduce Access Platform Line appeared first on BulkInside.

RETSCH’s new MM 500 control is the first mixer mill on the market that allows to monitor and control the temperature of a grinding process....

The post 365必威 appeared first on BulkInside.

The achievable temperature ranges from – 100 to 100 °C, with various options available for cooling and heating. The MM 500 control can be connected either to an LN2 supply or to an external temperature control unit such as a thermostat, chiller, or water tap. The sample is tempered by indirect cooling or heating by means of thermal plates. This patented concept from RETSCH eliminates the need for sample cooling, e. g. in open liquid nitrogen baths or with dry ice.

For cooling with liquid nitrogen, the mill can be equipped with the optional cryoPad. The innovative cryoPad technology enables the selection and maintenance of a defined cooling temperature in the range between -100 and 0 °C during grinding.

Besides classical size reduction processes, the MM 500 control is also suitable for mechanochemical applications where reactions can be significantly influenced by tempering the sample.

Benefits at a glance:

- Dry, wet and cryogenic grinding with up to 30 Hz

- Cooling and heating in a range from - 100 to 100 °C

- Continuous temperature monitoring throughout a grinding process

- cryoPad device extension for a temperature-controlled sample processing with LN2 in a range from -100 to 0°C.

- Fast sample processing and high throughput with two screw-lock jars of up to 125 ml each

- Patented hermetically closed system ensures safe operation with thermal fluids

Retsch is the leading solution provider for neutral-to-analysis sample preparation and characterization of solids. Based on more than 100 years of experience RETSCH develops innovative size reduction and sieving equipment which is characterized by excellent performance, operating convenience, safety and a long lifetime.

The post 365必威 appeared first on BulkInside.

Screw mixers provide a high-quality mix through the efficient multiple and progressive actions of the flights. Through the customisable screw design, paddle size and shape, angle of the blades, as well as operating parameters including material loading and speed of rotation, a high degree of flexibility and control can be provided over the mixing process, ensuring the mixing action suits the application and materials involved.

The mixer’s screws, or screws, provide gentle mixing, positively combining solid and liquid materials that differ in flow properties, particle size, or density and overcoming any characteristic that could result in segregation to deliver the desired mix. As homogeneity is quickly achieved this reduces work input, and therefore the energy requirements of the mixer, minimising the particle attrition and damage to any sensitive materials included.

These characteristics, when combined, make screw mixers ideal for processes that require continuous production.

Continuous Mixing

Ajax Equipment recently supplied leading European pre-fried and frozen potato product producer, Agristo, with a fourth continuous mixer, featuring an enhanced mirror polish finish, to enhance production capacity. The stainless steel twin screw mixer utilises a combination of paddle and Lynflow ribbon screw geometry to provide efficient though gentle mixing to grated potato and various additives, including flavourings, to produce a range of potato products with negligible damage to the ingredients. The continuous mixer also has a range of hygienic features, comprising a crack and crevice-free finish, easy to clean profile and the ability to hold water.

ribbon screw geometry to provide efficient though gentle mixing to grated potato and various additives, including flavourings, to produce a range of potato products with negligible damage to the ingredients. The continuous mixer also has a range of hygienic features, comprising a crack and crevice-free finish, easy to clean profile and the ability to hold water.

The mixer’s casing and covers feature a smooth figure of eight profile ensuring there are no ‘dead’ areas for the product to accumulate. While ease of access is assured with the counterbalanced covers needed on such a large mixer. The mixer also holds water making it easy to agitate the screws within the casing, which effectively becomes a bath for a cleaning cycle. Once cleaning is complete, the mixer’s gentle incline ensures it fully drains.

“Since commissioning Agristo’s first Ajax continuous mixers almost five years ago they have performed very well. As a result, when Agristo looked to expand its production in 2018 and 2020 continuing to work with Ajax was the obvious choice,” said Dieter Raes, technical director, Agristo.

For materials that require lower shear mixing, such as liquid chocolate and inclusions or flavourings, a single screw may suffice to achieve the desired blend. To ensure the consistent condition and quality of the chocolate it is necessary to keep the liquid at a constant temperature, this can be achieved using a water-heated jacket and sometimes heating the screw shaft as well. Inclusions can be quite varied in size, surface condition and density so, care in design is needed to ensure the correct intensity of mixing whilst avoiding trapping or damage to any friable inclusions.

When processing sticky materials, it is helpful for quality and hygiene reasons for the design of the screws’ flights to reflect this. The open form of ribbon flights helps prevent the build-up of material, which reduces the required frequency of maintenance, as well as allowing thorough cleaning to be easily carried out when required. Similarly, Ajax Equipment’s LynFlow paddle flights incorporate features for good mixing whilst resisting product build-up, making them easier to clean than standard quadrant paddles. It is also possible to include a ‘quick release’ feature, allowing screws to be easily changed for mixing different recipes.

paddle flights incorporate features for good mixing whilst resisting product build-up, making them easier to clean than standard quadrant paddles. It is also possible to include a ‘quick release’ feature, allowing screws to be easily changed for mixing different recipes.

Batch Mixing

While continuous screw mixers tend to offer greater flexibility, batch mixers can be better suited to some processes where the ability to load precise quantities of material in turn and the opportunity to measure and monitor quality batch by batch are beneficial or required.

Ajax Equipment recently developed a large capacity vertical screw blender for polymer powder production by a global chemical producer in South Korea. The stainless steel vertical screw blenders feature twin ‘fountain’ mixing screws, with each blender handling batches of up to 8T of polymer powder and additives. Crucial to the design is the pick-up characteristic of the vertical screw and the mass flow shape of the hopper. These ensure there are no dead spots in the blender and promotes the fullest mixing effect within a relatively short period of time.

Adaptable Design

With a design that can be altered to accommodate a wide range of materials and production needs as well as the option to produce continuously or in batches, screw mixers are well suited to provide effective and efficient mixing for a range of applications from food and confectionery production to chemical processing.

The post An Application-Based Design Ensures the Perfect Mix appeared first on BulkInside.

The post VICTAM Asia in co-location with Health &首先出现在BulkInside.

当前情况仍未达到预期的最佳状态。最重要的是,参展商和观众的健康以及活动的成功成果对组织者来说是最重要的。

In light of the recent increase in COVID-19 cases, which has forced the Royal Thai Government to implement new strict measures to control the spread of the pandemic, and the delays of the vaccination programs in several Asian countries, VICTAM and VIV do not see the opportunity to realize a large-scale event on the short term. Looking at the ongoing travel restrictions from and to Asia, the organizers also believe that it is not possible to guarantee the event quality as we know them. The postponement to the third quarter of 2022 is in the interest of the whole industry.

VICTAM Asia in co-location with Health & Nutrition Asia is thus rescheduled to September 7-9, 2022. The new venue selected is IMPACT Halls 9-10, in Bangkok, Thailand. The objective remains the same: to realize the Total Animal Feed and Health event.

The dates secured in September 2022 will give all stakeholders room to breathe and pay attention to other vital issues. The organizers’ mission is to present a strong, value-adding event to the industry with high benefits for all parties.

VICTAM Corporation and VIV worldwide will also continue their partnership in Europe in 2022 by co-locating VICTAM International and VIV Europe at the Jaarbeurs venue in Utrecht, the Netherlands, from May 31 – June 2, 2022. With the high percentage of vaccinations in Europe there is no reason to doubt that this show can successfully go on as planned.

The post VICTAM Asia in co-location with Health & Nutrition Asia are planned on September 7-9, 2022 appeared first on BulkInside.

如果在操作过程中出现问题,很容易导致生产瓶颈。在最坏的情况下,这将导致日常运营的延误....< / p > < p >的<一个rel =“nofollow”href = " //www.fxmrh.com/bulk-solids-handling/instrumentation-control/on-site-without-being-there/ " >在现场,没有被< / >第一次出现在< rel =“nofollow”href = " //www.fxmrh.com " > BulkInside < / >。< / p >

The employee at the machine puts on the glasses and starts the BEUMER Support app via voice command. The employee transmits a service number and a pin code to the hotline, and the connection with image and sound is established. The BEUMER technician receives the same image as the customer. The technician can directly give instructions and display all relevant information in the field of vision. The employee has both hands free to follow the instructions of the expert and carry out the necessary actions. Faults can be solved quickly and precisely – at any time. The BEUMER experts are available around the clock, seven days a week. Language barriers or the lack of specialized knowledge are no longer relevant for troubleshooting. Together with the user, we can also better validate why the fault occurred based on the recorded images.

As part of the comprehensive BEUMER Customer Support, users add the BEUMER Smart Glasses as an extension to their monthly or annual hotline service agreement. Together with BG.evolution, the BEUMER Group is currently developing further digital products under the umbrella of “Smart Solutions”.Many of our customers are already showing clear interest in the BEUMER Smart Glasses.

The post On Site, Without Being There appeared first on BulkInside.

At Codelco, the advantages were quickly recognized. Up to now, conveyor belt seals have been replaced at short intervals in many plants due to wear. The performance of conventional conveyor seal skirting lasts for a maximum of 2 days under load. In addition, every exchange also means process downtime at the same time.

These downtime costs, maintenance costs and cleaning costs to avoid or remove dust and spills are eliminated with the use of the AirScrape. The belts are also protected by the contact-free operation of this chute seal and new investments for belts and seals are reduced. In addition to the economic efficiency through the use of the AirScrape, you can also see sustainability at Codelco.

For example, the greater cleanliness and freedom from dust of the operating facilities now ensure the health and safety of employees. This also increases the motivation of those who normally struggle with dust and dirt. They recognize this as an appreciation of their employer – soft skills that such a large company like Codelco also appreciates.

The post Contactless Conveyor Skirting for Codelco, the “AirScrape” appeared first on BulkInside.

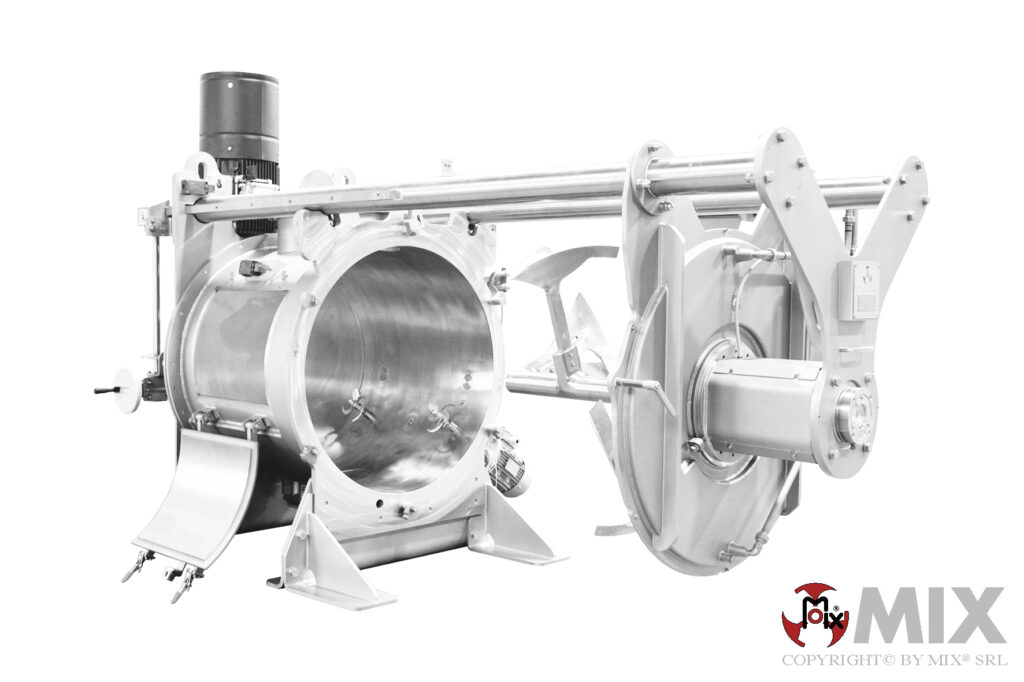

自1990年以来,MIX s.r.l.在Cavezzo (Modena)的混合系统和散装固体处理工业组件的项目和制造....必威最新地址< / p > < p >的<一个rel =“nofollow”href = " //www.fxmrh.com/bulk-solids-handling/mixers-blenders/industrial-mixers-equipped-with-fully-extractable-rotor-shaft/ " >工业搅拌机配备完全可榨出的转子轴< / >第一次出现在< rel =“nofollow”href = " //www.fxmrh.com " > BulkInside < / >。< / p >

MIX开发了一系列配备有充分萃取转子轴工业混合器。这种创新解决方案使操作员能够在混合室内轻松进入任何点,并允许获得混合壁和转子轴的完全清洁。

调音属于该范围内具有最大的几何13.000升容量,配备有换热器,侧菜刀,和用于液体喷射喷嘴,并适合于在ATEX区域运行。

这些特点使混频器适用于许多应用中应用的多个领域食品,化工,制药,在此,配方的每次改变清洁设备具有巨大重要性。 <人物类= “WP-块廊列-3裁剪”> Each mixer is designed so as to be able to optimally perform the productive tasks, for which it has been conceived. This series of mixers with fully extractable rotor shafts is positioned at the top range, intended for customers who consider the quality of their product an essential characteristic to distinguish themselves in the market. Certification Systems according to ISO 9001 – ISO 140001 – ISO 45001. The post Industrial Mixers Equipped With Fully Extractable Rotor Shaft appeared first on BulkInside.

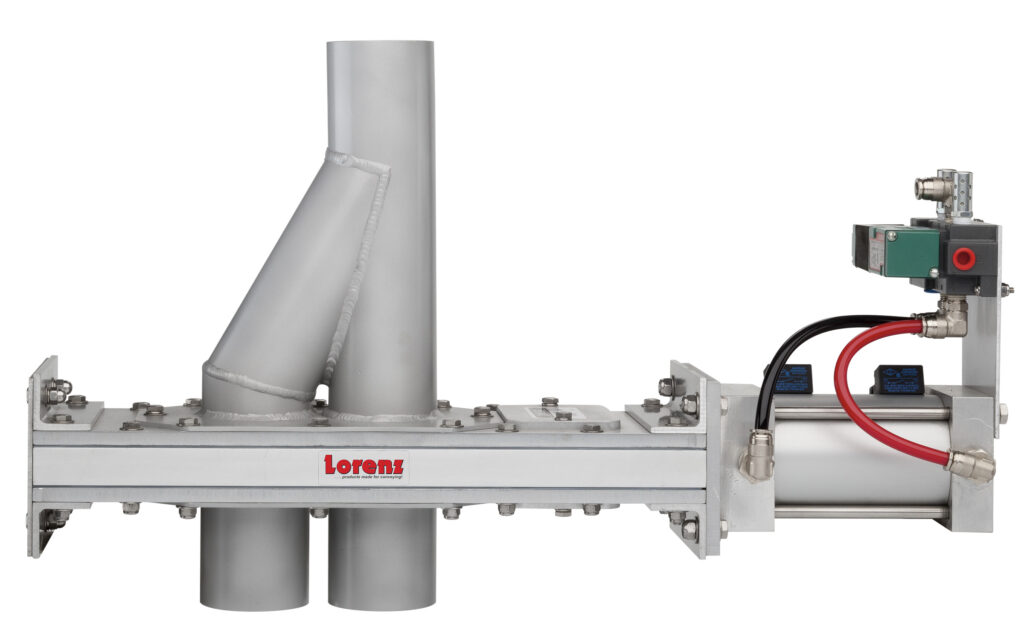

洛伦兹输送产品制造专用于真空的2,3或4路分流阀;稀相压力输送系统。额定温度为…

The post The Lorenz Series “BulkInside.

Lorenz Diverter Valves can be installed either horizontally or vertically to meet your specific line requirements.

Lorenz Diverter Valves can be installed either horizontally or vertically to meet your specific line requirements.

Double acting, internal magnetic, cushioned air cylinders, and choice of solenoids allow custom configurations. Choices of inlet & outlet materials and coupling connections enhance the flexibility of the valve.

Standard delivery time is two weeks, but if delivery is critical, choose Lorenz Lightning Ship and have your order ship the same day!

Lorenz manufactures components for every stage of the process. Diverter Valves, Slide Gates, Maintenance Gates, Couplings, Elbows, Fittings, Cyclones, even Iris Valves.

Website: www.lorenzproducts.com

Toll Free: U.S.A. 1-800-263-7782 || Canada 1-800-263-1942

E-Mail: sales@lorenz.ca

The post The Lorenz Series “D” Diverter Valve appeared first on BulkInside.